In a typical manufacturing process, direct manufacturing costs include direct materials and direct labor. However, they may also include the cost of supplies that are directly used in production process, and any other direct expenses that don’t fall under direct materials and direct labor categories. Prime costs are calculated based on the direct labour costs and the total cost of the raw materials.

Reduced Energy Consumption – How Does Automation Affect Conversion Cost?

- Overhead costs, also known as indirect costs, are incurred by a business to maintain its operations but cannot be directly attributed to a specific product or service.

- Management needs to understand its costs in order to set prices, budget for the upcoming year, and evaluate performance.

- This information can be useful for cost accounting and management purposes, which we will discuss in the next topics.

- Cost accounting methods such as job costing and process costing can help a company accurately track and report conversion costs.

- In summary, conversion cost bridges the gap between raw materials and finished products.

- In summary, conversion cost analysis empowers organizations to make informed decisions, optimize processes, and remain competitive in dynamic markets.

Some other examples of manufacturing overheads are insurance, building maintenance, machine maintenance, taxes, equipment depreciation, machining, and inspection. For example, if the conversion cost per unit is $9 and the raw material cost per unit is $3, the total production cost per unit is $12. To plan the production budget, the conversion cost per unit can be multiplied by the expected number of units to be produced in the future. Yes, conversion costs can change based on factors like labor conversion costs rates, overhead expenses, and efficiency improvements. Conversion costs are fundamental in cost accounting, guiding businesses in analyzing and optimizing production processes. Focusing on these costs helps identify inefficiencies and improve product quality.

Estimating Closing Stock for Precise Financial Reporting

- That means all product costs need to be put into the numerator of a cost per equivalent unit calculation.

- Segmentation plays a crucial role in the success of any e-commerce business.

- Automated processes can improve workplace safety by reducing the risk of accidents and injuries.

- Direct material cost encompasses the expenses related to raw materials used in production.

- Process costing firms usually have several departments that products must pass through before they’re complete.

- Utilizing the formula provided, companies can calculate conversion costs accurately, allowing for better cost control and resource allocation.

Let’s assume a unit in ending WIP is about halfway through the process of completion. It would be natural to assume it is about 50% complete (and thus equal to 0.5 equivalent units). When each individual product unit is the same, managers are not going to spend time thinking about individual product units—they’re all the same! Instead they spend time thinking about and trying to improve the processes that spit out those individual product units. Accurately tracking and reporting conversion cost is crucial for businesses to make informed decisions and improve cash flow their operations. By keeping these factors in mind and staying up to date with best practices, businesses can effectively manage conversion cost and drive long-term success.

3 Equivalent Units Calculations (STEP #

In a processing environment, there are two concepts important to determining the cost of products produced. As you have learned, equivalent units are the number of units that would have been produced if one unit was completed before starting a second unit. For example, four units that are one-fourth finished would equal one equivalent unit. Sometimes individuals become managers due to their knowledge of the production process but not necessarily the costs.

Fluctuating Labor Costs – Some Common Challenges Associated with Calculating Conversion Cost

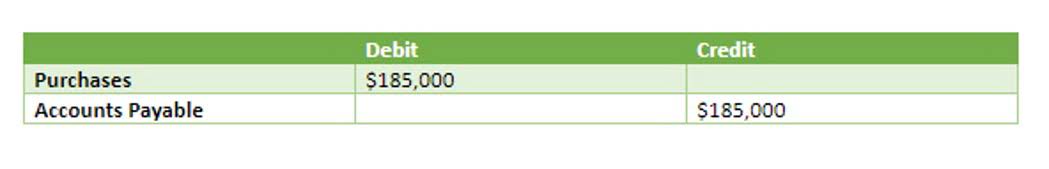

Direct labor cost amounted to $200,000 and factory overhead is estimated at $250,000 based on direct labor hours. In terms of direct labor, prime costs overlap with conversion costs but emphasize labor’s role in transforming raw materials into finished goods. Comparing conversion costs with prime costs provides a dual perspective on cost structures, aiding strategic planning and resource allocation. Online Bookkeeping Direct materials, a key component of prime costs, are raw materials traceable to specific products.

Direct Labor

- For responsibility accounting purposes these departments costs should be kept separate.

- Manufacturers can reduce energy consumption by implementing energy-efficient technologies, such as LED lighting and equipment, and by implementing energy management systems to monitor and control energy usage.

- This means that prime cost includes the cost of raw materials, which are not included in conversion cost.

- Calculating conversion cost is essential because manufacturers can determine the total product cost.

- For example, if your conversion metric is signing up for your email list, the signup form should be prominent.

- In this example, the total conversion cost for producing 100 widgets amounts to $800.

By implementing these strategies, businesses can maximize their return on investment and achieve sustainable growth. Remember that small adjustments can yield significant results, so experiment, learn, and adapt to stay ahead in the competitive landscape. So the cost of beginning WIP, the first-in and first-out portion of the units completed and transferred out is reflected below. So, the beginning WIP equivalent units are subtracted away in order to arrive at “Equivalent units completed with this period’s work” (see cells E4, E11, and E18).